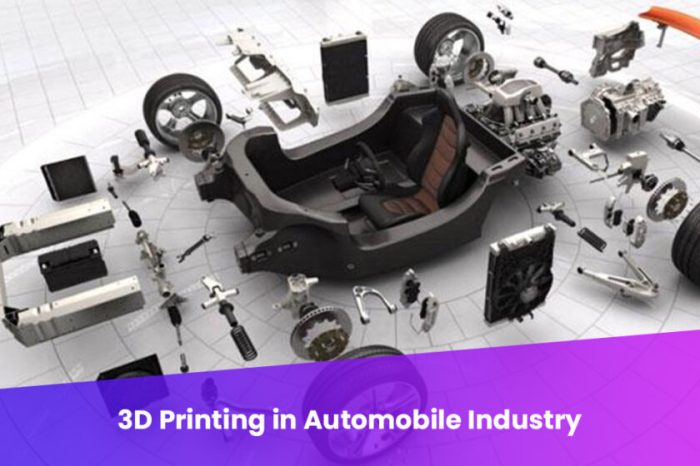

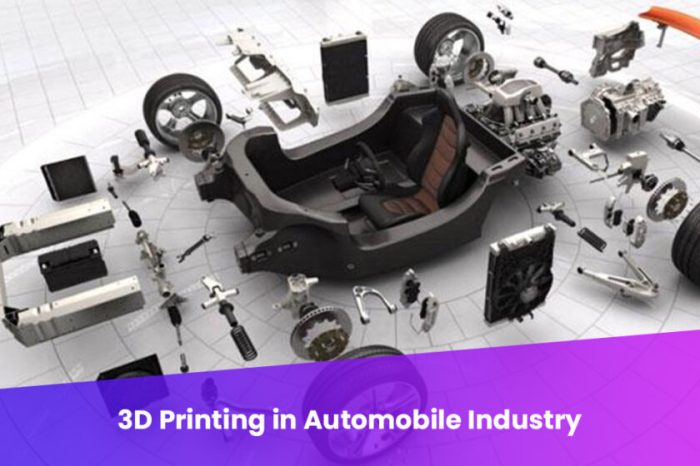

Manufacturing Process Revolution

D printing, or additive manufacturing, is rapidly transforming the automotive industry’s manufacturing processes, offering significant advantages over traditional subtractive methods like casting and machining. This shift is driven by the technology’s ability to create complex geometries, reduce material waste, and accelerate production cycles.Additive manufacturing allows for the creation of parts with intricate designs and internal structures that are impossible or extremely difficult to produce using conventional methods.

This opens up new possibilities for lightweighting vehicles, improving performance, and enhancing design flexibility. The ability to produce customized parts on demand also streamlines production and reduces lead times.

Impact on Production Speed and Efficiency

D printing significantly accelerates the production of certain automotive parts. Traditional methods often involve multiple steps, such as creating molds, casting, machining, and finishing. Additive manufacturing consolidates many of these steps into a single process, dramatically reducing the overall production time. This speed advantage is particularly beneficial for prototyping, low-volume production runs, and the creation of highly customized components.

For example, the rapid prototyping capabilities of 3D printing enable engineers to iterate designs quickly, leading to faster product development cycles. The ability to produce on-demand tooling also reduces downtime and accelerates manufacturing processes.

Cost-Effectiveness of 3D Printing

The cost-effectiveness of 3D printing compared to traditional methods depends heavily on factors like part complexity, production volume, and material costs. For low-volume production and highly complex parts, 3D printing can be more cost-effective due to reduced tooling costs and simplified manufacturing processes. However, for high-volume production of simple parts, traditional methods often remain more economical. The upfront investment in 3D printing equipment can also be a significant factor, but the long-term savings from reduced material waste and faster production can offset this initial cost.

A key consideration is the potential for design optimization through topology optimization software, which allows engineers to create lighter and stronger parts using less material.

Suitable Automotive Parts for 3D Printing

Several types of automotive parts are particularly well-suited for 3D printing. These include complex geometries such as internal combustion engine components, lightweight structural parts, customized interior trims, and tooling for manufacturing processes. The ability to create intricate lattice structures for lightweighting and enhanced strength makes 3D printing ideal for applications where weight reduction is critical, such as in electric vehicles.

Further, the ability to produce highly customized parts, such as personalized dashboards or bespoke trim pieces, makes 3D printing attractive for high-end vehicles and niche markets.

Material Properties Comparison

| Property |

3D Printed Parts (e.g., Nylon, ABS, Metal Alloys) |

Traditionally Cast/Machined Parts (e.g., Aluminum, Steel) |

| Strength |

Varies widely depending on the material and printing process; generally lower than traditional methods for some materials. |

Generally high, depending on the alloy and manufacturing process. |

| Durability |

Varies depending on material and post-processing; can be durable with appropriate material selection and treatment. |

Typically high, depending on the material and manufacturing process. |

| Surface Finish |

Can be rough; often requires post-processing for smoother surfaces. |

Generally smoother, depending on the machining process. |

| Cost |

Can be lower for low-volume, complex parts; higher for high-volume production. |

Can be lower for high-volume, simple parts; higher for low-volume, complex parts. |

Design and Prototyping Advancements

D printing has revolutionized automotive design and prototyping, offering unparalleled speed, flexibility, and cost-effectiveness compared to traditional methods. This technology allows manufacturers to iterate designs rapidly, create intricate parts previously impossible to produce, and significantly reduce the time and expense associated with bringing new vehicles to market.The ability to quickly create physical prototypes is a game-changer in automotive design.

Instead of relying on lengthy and expensive tooling processes, engineers can now print functional prototypes in a matter of hours or days, allowing for immediate evaluation and design refinement. This iterative process leads to better designs, improved functionality, and reduced development time.

Rapid Prototyping in Automotive Design

D printing’s speed and efficiency drastically accelerate the prototyping process. Designers can quickly test different iterations of a component, evaluating its form, fit, and function before committing to expensive tooling. This iterative design approach allows for early detection and correction of design flaws, ultimately resulting in a superior final product. For example, a car door handle might undergo several iterations, printed in different materials to test durability and ergonomics, before the final design is selected.

Creation of Complex and Customized Automotive Parts

Additive manufacturing, the technical term for 3D printing, excels at creating intricate geometries and complex internal structures that are impossible or prohibitively expensive to produce using traditional subtractive manufacturing methods. This capability allows automotive manufacturers to create lightweight, high-strength parts with optimized performance characteristics. For instance, lattice structures can be incorporated into components to reduce weight without compromising strength, improving fuel efficiency and vehicle performance.

Further, customized parts can be easily produced, catering to specific customer needs or adapting to unique vehicle configurations.

Examples of Innovative Automotive Designs Enabled by 3D Printing

Several automotive companies are already leveraging 3D printing to create innovative designs. For example, some manufacturers are using 3D-printed parts in race cars to reduce weight and improve performance. These parts often feature intricate internal structures optimized for strength-to-weight ratio, providing a competitive edge. Another example is the production of personalized interior components, such as custom-designed dashboards or air vents, offering a higher level of customization and personalization for customers.

Furthermore, the use of 3D printing in the creation of tooling for production processes is becoming increasingly common, enabling faster production and reduced tooling costs.

Benefits of 3D Printing for Testing and Iterating Designs

The ability to rapidly test and iterate designs is a significant advantage of 3D printing. Engineers can print multiple versions of a part with slight modifications, allowing for quick evaluation and comparison. This iterative process facilitates the optimization of design parameters, such as material properties, structural integrity, and aerodynamic performance. The cost-effectiveness of 3D printing makes it feasible to conduct extensive testing with numerous prototypes, leading to a more robust and reliable final product.

The speed at which iterations can be produced allows for quicker decision-making, accelerating the overall development process.

Hypothetical Scenario: Development of a New Vehicle Feature

Let’s imagine an automaker is developing a new active aerodynamic system for a sports car. Using 3D printing, engineers can rapidly prototype different designs for the system’s components, such as adjustable spoilers and air deflectors. They can print these components in various materials to assess their performance under different conditions, simulating high speeds and varying airflow patterns. They can then iterate on the designs based on the test results, quickly refining the system until it meets the desired performance specifications.

This iterative process, enabled by 3D printing, significantly reduces the development time and cost compared to traditional methods, allowing the automaker to bring the innovative aerodynamic system to market more quickly and efficiently. The ability to create complex geometries, such as internal channels for air flow control, is a significant advantage of 3D printing in this context.

Material Innovation and Customization

D printing’s impact on the automotive industry extends beyond manufacturing processes and design; it significantly alters the landscape of material usage and allows for unprecedented levels of customization. The ability to precisely deposit materials layer by layer opens doors to using materials previously unsuitable for traditional manufacturing methods, leading to lighter, stronger, and more specialized automotive components.The adoption of new materials in additive manufacturing for automotive applications is driven by the need for improved performance, reduced weight, and enhanced design flexibility.

This section will explore several key materials, their properties, and their suitability for various automotive parts, ultimately highlighting the potential for personalized vehicle interiors.

New Materials Used in 3D Printing for Automotive Applications

Several innovative materials are finding their niche in automotive 3D printing. These include high-performance polymers like ULTEM (polyetheretherketone), PEEK (polyetheretherketone ketone), and Nylon, along with composites reinforced with carbon fiber or other materials. Metals such as aluminum, titanium, and stainless steel are also increasingly utilized, depending on the application’s specific requirements. The selection depends heavily on the desired properties of the final part, such as strength, weight, temperature resistance, and chemical resistance.

Material Properties and Suitability for Different Parts

ULTEM, known for its high-temperature resistance and chemical stability, is suitable for under-the-hood components exposed to extreme heat and harsh chemicals. PEEK, another high-performance polymer, offers excellent mechanical strength and chemical resistance, making it ideal for demanding applications such as engine parts or safety-critical components. Nylon, while less robust, provides flexibility and cost-effectiveness for less demanding parts like interior trim pieces.

Metal 3D printing allows for the creation of complex, lightweight parts with high strength-to-weight ratios, making them ideal for chassis components or engine parts. Carbon fiber reinforced polymers (CFRPs) offer exceptional strength and stiffness while remaining lightweight, making them suitable for body panels and structural components.

Performance Comparison of 3D-Printed Parts from Different Materials

A direct comparison requires specifying the application and the performance metrics being considered. For instance, a comparison between a 3D-printed ULTEM part and a 3D-printed aluminum part for a high-temperature application would focus on heat deflection temperature, tensile strength, and weight. Generally, metals like aluminum offer higher strength and stiffness compared to polymers, but polymers often provide better flexibility and lower weight.

CFRPs would typically outperform both in terms of strength-to-weight ratio. The choice depends on the specific needs of the component. For example, a lightweight interior component might prioritize a polymer like Nylon for its low weight and cost-effectiveness, whereas a structural component might necessitate the higher strength of aluminum or the superior strength-to-weight ratio of a CFRP.

Potential for Customized and Personalized Automotive Interiors

D printing’s ability to create intricate geometries and complex designs opens up a world of possibilities for personalized automotive interiors. Imagine dashboards tailored to individual driver preferences, customized door handles with embedded controls, or unique air vent designs. The ability to produce small-batch or even one-off interior parts enables automakers to offer highly personalized options, enhancing the customer experience and differentiating their products.

This level of customization can extend to incorporating unique textures, colors, and materials to perfectly match a customer’s taste. For example, a customer could choose a specific wood grain pattern for their dashboard trim, or a unique color for their gear shift knob.

Advantages and Disadvantages of Using Various 3D Printing Materials in the Automotive Industry

The selection of 3D printing materials involves careful consideration of several factors. Here’s a summary of the advantages and disadvantages:

- High-Performance Polymers (ULTEM, PEEK):

- Advantages: High strength, temperature resistance, chemical resistance.

- Disadvantages: Higher cost, potentially slower printing speeds compared to some other materials.

- Nylon:

- Advantages: Cost-effective, flexible, relatively fast printing speeds.

- Disadvantages: Lower strength and temperature resistance compared to high-performance polymers.

- Metals (Aluminum, Titanium):

- Advantages: High strength, stiffness, durability.

- Disadvantages: Higher cost, potentially longer printing times, more complex post-processing.

- Carbon Fiber Reinforced Polymers (CFRPs):

- Advantages: High strength-to-weight ratio, excellent stiffness.

- Disadvantages: High cost, complex manufacturing process, potential for fiber misalignment during printing.

Supply Chain and Logistics Transformation

D printing is revolutionizing automotive supply chains, moving away from traditional, centralized manufacturing models towards more agile and responsive systems. This shift allows for greater flexibility, reduced costs, and faster response to market demands. The ability to produce parts on-demand and closer to the point of need is transforming how automotive companies manage their logistics and procurement processes.On-Demand Manufacturing and Localized ProductionThe capacity for on-demand manufacturing is a key benefit of 3D printing in the automotive industry.

Instead of maintaining large inventories of parts that may become obsolete or unnecessary, manufacturers can produce parts only when needed. This significantly reduces storage costs and minimizes the risk of obsolescence. Localized production, enabled by 3D printing, brings manufacturing closer to assembly plants or even directly to customers. This reduces transportation costs and lead times, leading to increased efficiency and responsiveness.

For example, a car manufacturer might establish 3D printing facilities in different regions to produce customized or replacement parts for vehicles in those specific areas. This minimizes shipping distances and time, and allows for quicker repairs and maintenance.Lead Time Reduction and Inventory Cost SavingsD printing significantly reduces lead times for automotive parts. Traditional manufacturing methods often involve long lead times due to tooling, production scheduling, and transportation.

With 3D printing, the lead time is drastically shortened, as parts can be printed on-demand, eliminating the need for lengthy manufacturing processes. This agility allows for faster responses to unexpected demand fluctuations or urgent repair needs. Consequently, inventory costs are dramatically reduced. By producing parts only when needed, companies can minimize warehousing space and reduce the risk of parts becoming obsolete or damaged while in storage.

A study by HP, for example, showed a 70% reduction in lead time for certain parts using 3D printing compared to traditional methods.Just-in-Time Manufacturing for Automotive PartsD printing facilitates just-in-time (JIT) manufacturing, a lean manufacturing approach where parts are produced only when needed, minimizing inventory holding costs and waste. This approach is particularly advantageous for low-volume, high-variety production, common in the automotive industry, particularly for specialized or customized components.

For instance, a manufacturer might use 3D printing to produce custom interior trims or specialized tooling for a particular vehicle model, only when those components are required for assembly, aligning perfectly with the JIT manufacturing philosophy.Streamlined Supply Chain Process FlowchartThe following describes a flowchart illustrating the streamlined supply chain process enabled by 3D printing in automotive manufacturing.Imagine a flowchart with the following steps:

1. Design and Engineering

The design of a part is finalized using CAD software.

2. 3D Printing

The digital design is sent to a 3D printer, and the part is printed on-demand.

3. Quality Control

The printed part undergoes quality checks to ensure it meets specifications.

4. Direct Integration

The part is directly integrated into the assembly line or shipped directly to the customer/repair center.

5. Inventory Management

Minimal inventory is maintained, only holding essential components.

6. Data Analysis

Data on production, usage, and potential improvements are collected and analyzed.This streamlined process eliminates many steps involved in traditional manufacturing, resulting in a faster, more efficient, and cost-effective supply chain.

Sustainability and Environmental Impact

D printing, also known as additive manufacturing, offers a compelling pathway towards a more sustainable automotive industry. Its potential to reduce waste, lower energy consumption, and enable the use of recycled materials presents a significant opportunity to lessen the environmental footprint of vehicle production. This section delves into the specific ways 3D printing contributes to a greener automotive sector.

The environmental benefits of 3D printing in automotive manufacturing stem from its inherent ability to produce parts only as needed, minimizing material waste and reducing energy consumption compared to traditional subtractive manufacturing methods. This contrasts sharply with conventional processes like casting or machining, which often involve significant material removal and generate substantial waste. Furthermore, the localized nature of 3D printing allows for on-demand production, reducing transportation needs and associated emissions.

Waste Reduction and Material Consumption

D printing significantly reduces material waste by creating parts directly from a digital design, eliminating the need for extensive machining or casting processes that generate large amounts of scrap. For example, in traditional manufacturing, creating a complex part might involve starting with a large block of metal and removing excess material, resulting in a considerable amount of waste. 3D printing, on the other hand, only uses the precise amount of material required to build the part, minimizing waste and maximizing material efficiency.

This translates to lower raw material costs and a smaller environmental impact. The precision of 3D printing also minimizes the need for rework or rejects, further reducing material waste.

Comparison of Carbon Footprints

A comprehensive life cycle assessment (LCA) comparing the carbon footprint of traditional manufacturing with 3D printing reveals a complex picture. While 3D printing’s localized production and reduced material waste offer advantages, the energy consumption of the printing process itself needs consideration. The overall environmental impact varies significantly depending on factors such as the material used, the size and complexity of the part, the type of 3D printing technology employed, and the energy source used for the process.

However, studies suggest that for certain applications, particularly in the production of complex, customized parts, 3D printing can offer a lower overall carbon footprint than traditional methods. For instance, a study by researchers at the University of Michigan showed that 3D printing of certain automotive components resulted in a 20-30% reduction in carbon emissions compared to conventional manufacturing.

Utilization of Recycled Materials

The potential for incorporating recycled materials in 3D printing for automotive parts is a significant area of ongoing research and development. Several types of recycled materials, including plastics and metals, are being successfully used in additive manufacturing processes. This offers a pathway to reduce reliance on virgin materials and promote a circular economy within the automotive industry. For instance, researchers are exploring the use of recycled ABS and nylon plastics in 3D printing for interior components, while studies are underway to utilize recycled aluminum alloys for the production of lightweight automotive parts.

The challenge lies in ensuring the quality and consistency of recycled materials to meet the stringent performance requirements of automotive applications.

Vision for a Sustainable Automotive Manufacturing Process

A sustainable automotive manufacturing process heavily reliant on 3D printing envisions a decentralized production model where parts are manufactured on-demand at regional hubs or even within individual dealerships. This would drastically reduce transportation needs and associated emissions. The use of recycled and bio-based materials would minimize the environmental impact of raw material sourcing. Furthermore, design optimization using generative design software, coupled with 3D printing, could lead to the creation of lighter, more fuel-efficient vehicles with reduced material usage.

This vision includes a robust system for collecting and recycling end-of-life automotive parts, creating a closed-loop system where materials are continuously reused and repurposed, minimizing waste and maximizing resource efficiency. This approach, though ambitious, aligns with the growing push for sustainable manufacturing practices across various industries.